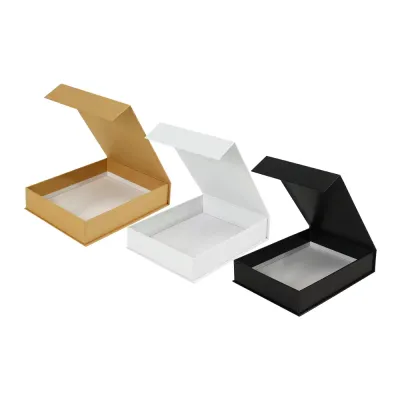

Select the color

Select Variant

Select quantity

Mug Packaging Box Manufacturing

Introduction

In the world of gifting and branding, packaging plays a pivotal role in making a lasting impression. Mug packaging boxes, in particular, have evolved from simple containers to creative works of art that protect, enhance, and showcase the value of the enclosed mugs. This blog post delves into the comprehensive process of mug packaging box manufacturing, shedding light on the techniques, materials, and innovations that bring these boxes to life.

1. Design and Conceptualization

The journey of a mug packaging box begins with a creative spark. Designers collaborate to conceptualize a box that not only snugly accommodates the mug but also conveys the brand's identity or the sentiment behind the gift. This stage involves sketching, digital rendering, and prototyping to ensure the dimensions are just right.

2. Material Selection

Choosing the right material is crucial to achieving the desired aesthetics and functionality. Cardboard, paperboard, and corrugated board are popular choices due to their durability and printability. Recycled and eco-friendly materials are increasingly favored to align with sustainability goals.

3. Printing and Customization

Printing techniques like offset, digital, and screen printing are employed to transform the chosen material into a canvas of branding and creativity. Brands often incorporate their logo, colors, and artwork to make the packaging unique and recognizable.

4. Die-Cutting and Folding

Precision is key during the die-cutting and folding stage. Specialized machinery creates precise cuts and scores to ensure the packaging box can be assembled seamlessly. Folding lines are strategically placed to facilitate easy assembly.

5. Gluing and Assembly

The components of the packaging box are carefully glued and assembled to ensure structural integrity. Automated gluing machines or skilled craftsmen meticulously bring the pieces together to form the final box.

6. Finishing Touches

Finishing touches enhance the overall appeal of the packaging. This can involve spot varnishing, embossing, debossing, or adding special textures to create a tactile experience for the recipient.

7. Quality Control

Quality control ensures that each box meets the highest standards. Inspections are conducted to verify accuracy in dimensions, print quality, and overall appearance.

8. Packaging and Distribution

Once the mug packaging boxes pass quality control, they are carefully packaged to prevent damage during transportation. The boxes are distributed to various retail outlets, gift shops, or directly to customers, ready to delight and impress.

Conclusion

The journey of a mug packaging box, from concept to completion, is a symphony of design, craftsmanship, and innovation. These boxes not only safeguard the mugs within but also convey a sense of care and thoughtfulness. The fusion of art and engineering in mug packaging box manufacturing demonstrates the power of packaging to elevate the value of its contents and leave a lasting impression on recipients.

| Product Name | Item Weight( Kg ) | Pieces in Pack | Carton Weight ( Kg ) | Carton Size ( Cm ) |

| Mug Packaging Box SKU: 147-GB | 0.0250 | 240 | 6.0000 | 70x40x30 |

| Gift Box SKU: ELGBK-01 | 0.0000 | 100 | 0.0000 | 0 |

| Mug Packaging Box SKU: 147-GB | 0.0250 | 240 | 6.0000 | 70x40x30 |

| Black Gift Box for corporate Gifting SKU: GB-BK | 0.0100 | 100 | 0.0000 | 0.0 |